- Home

- /

- Products

- /

- Product Level 1

- /

- Rotary Valves – DMN-WESTINGHOUSE

Rotary Valves – DMN-WESTINGHOUSE

Bulk Material Handling Solutions

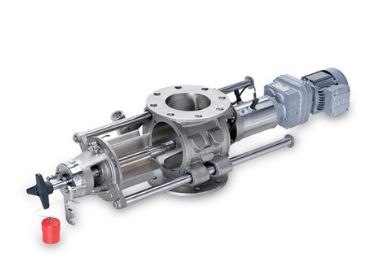

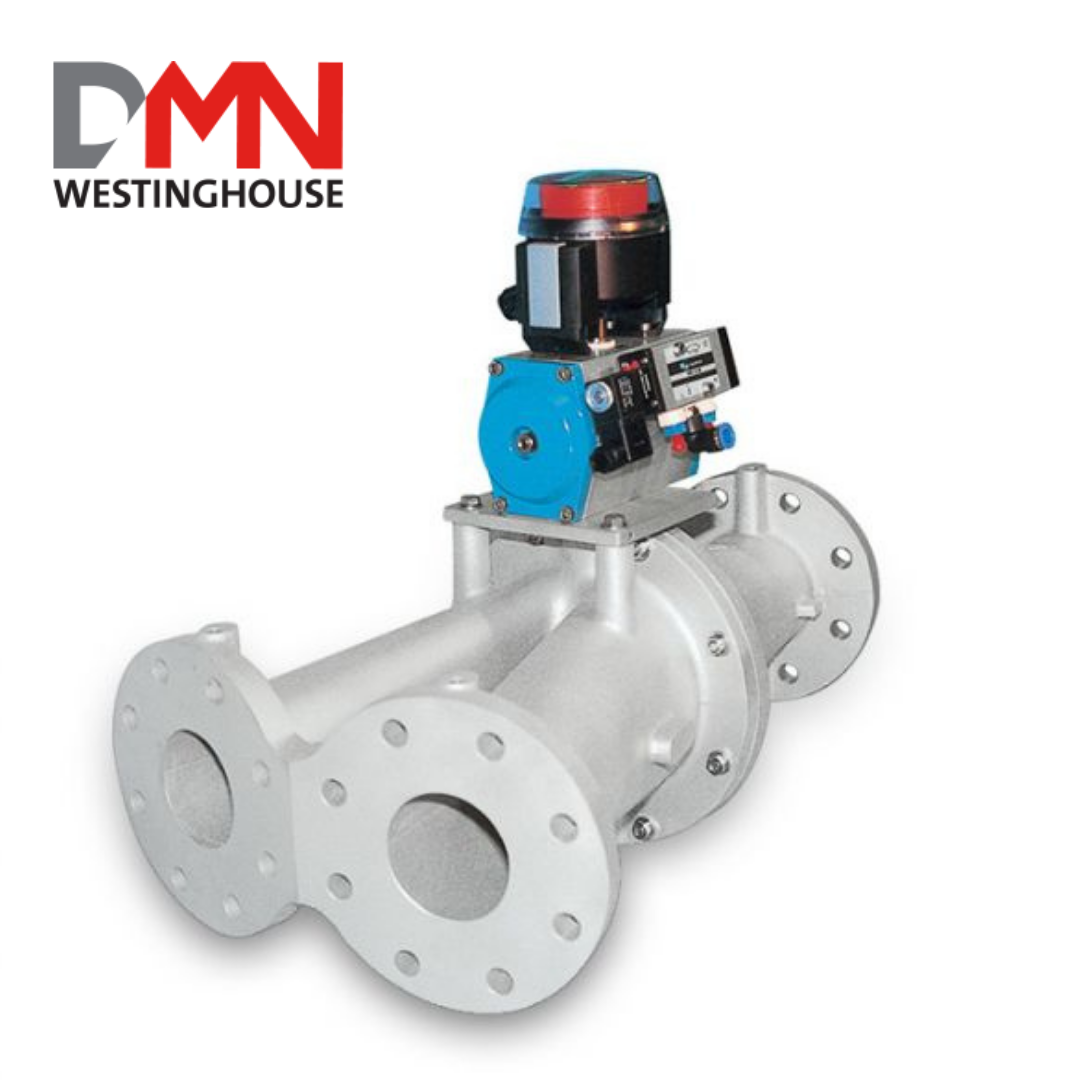

Rotary valves are essential in bulk material handling, enabling accurate control of material flow and reducing air leakage in pneumatic conveying and dense phase systems. Carefully designed rotor tips and valve bodies support consistent performance in industries such as food processing, wastewater treatment, and animal feed.

At LGPM, we provide a range of DMN-WESTINGHOUSE rotary valves suited to the food and animal feed sectors. These rotary valves are available in sizes from 100mm to 500mm, addressing specific industry requirements.

Understanding Rotary Valves

Rotary valves (airlocks) regulate material flow between chambers while controlling air leakage. They are essential for bulk material handling of powders and granules. Drop-through designs such as the AL/AXL Rotary Valves provide consistent feeding in pneumatic conveying and gravity discharge systems.

In dust extraction systems, reliable dust-lock rotary valves such as the DL Series help maintain effective dust collection.

In the food processing industry, hygienic options like the SAL Sanitary Rotary Valves deliver precise dosing with polished stainless finishes. Together with partners such as Pneuvay Engineering, LGPM supplies high-quality rotary feeders trusted across wastewater treatment, animal feed, and dairy processing applications.

Key Engineering Features

Precision Engineering & Hygiene

- Polished stainless-steel surfaces (~0.8 µm Ra, 150 grit) reduce build-up and prevent bridging.

- Chamfered rotor vanes help protect fragile powders during flow.

- Hygienic models like the AL/AXL Dairy Rotary Valves and BL/BXL Dairy MZC Slide Rail Valves meet USDA and EHEDG standards.

Compliance with International Standards

- Meets Australian Standards, USDA, EHEDG, ATEX 2014/34/EU, NFPA 69, and EC 1935/2004 standards.

- Ensures high hygiene, safety, and cleanability, ideal for food, dairy, and pharmaceutical applications.

Modular & Configurable Design

- Sizes: From 100 mm to 500 mm, to suit a wide range of material flow rates.

- Rotor types: Fixed blades, adjustable blades, scalloped, and reduced-capacity options.

- Specialised solutions:

- AML Large-Inlet Valves for powders

- MLD Low-Pressure Valves for vacuum conveying

- MALD Medium-Duty Valves for general powder handling

- GL Rotary Valves minimise product degradation, making them ideal for pellets, beans, and grain

Hygiene & Reduced Downtime

- Easy-clean systems like the AL/AXL Dairy MZC with Slide Rails allow quick rotor removal for maintenance.

- Blow-through designs such as the BL/BXL/BXXL Rotary Valves reduce air leakage in pneumatic lines and support efficient product conveying.

Rotary valves by DMN-WESTINGHOUSE are widely used in bulk material handling operations across the world. Integrated with equipment such as industrial fans, hammer mills, and pressure monitoring tools, they support smooth, consistent flow in a range of applications, from dust filtration to advanced material conveying, making them a key component in modern processing systems.

Benefits For Your Application

Proven performance across a wide range of dry powders and granular materials

Designed for quick disassembly, enabling fast maintenance and reduced downtime

High filling efficiency to support consistent material flow and process reliability

Component Specifications

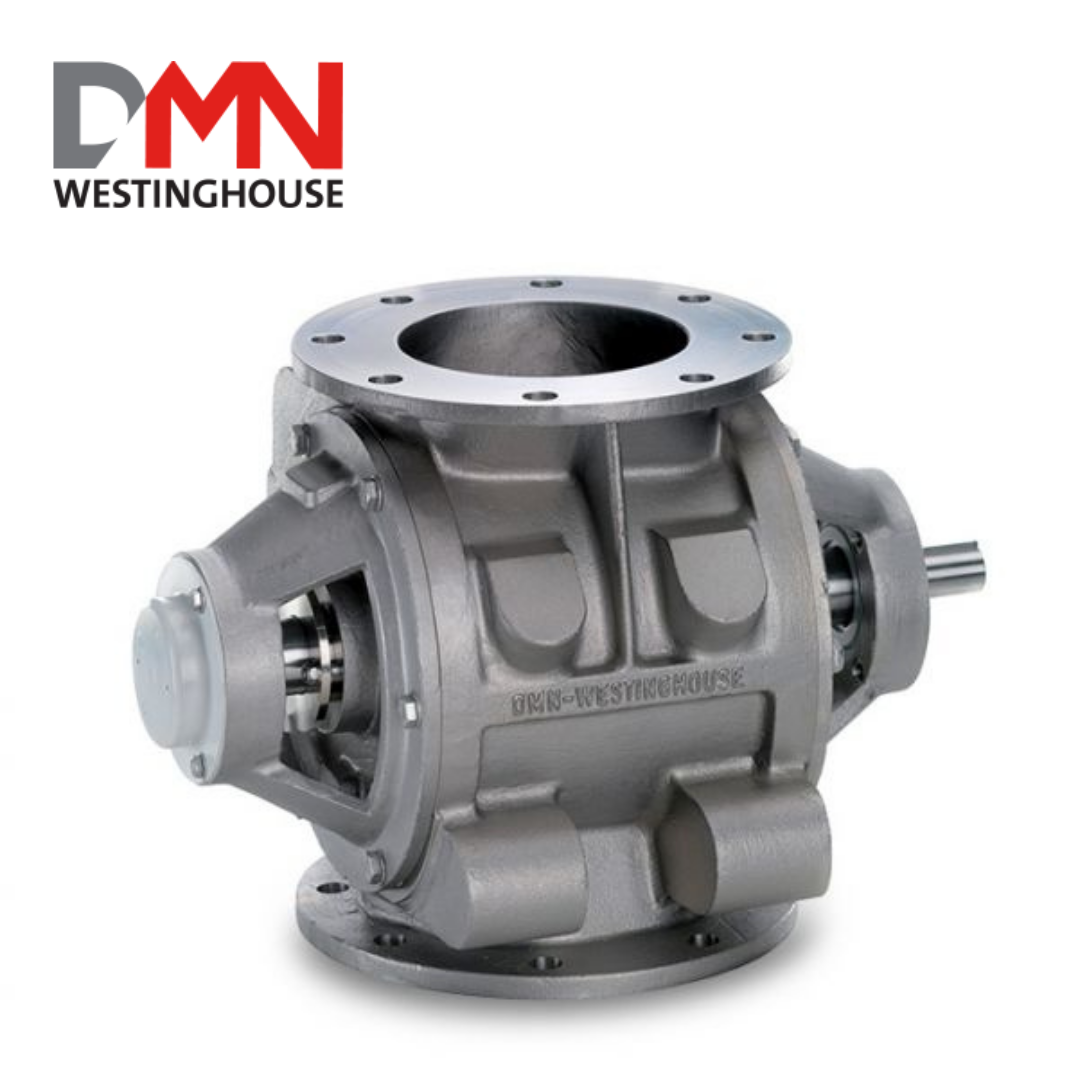

Bodies

- Cast Iron, Stainless Steel (316), and Aluminium (LM25);

- Precision-cast and bored with optional hard chrome or electroless nickel coatings for wear resistance.

End Covers

- Cast Iron, Stainless Steel, or Aluminium;

- Spigot-located for concentric alignment.

- Quick-release options available on MZC models for easy maintenance.

Rotor

- Fabricated in Mild or Stainless Steel (316L);

- Available in fixed, adjustable, scalloped, or reduced-capacity designs.

- Chamfered blades reduce product damage; coating options include polyurethane or PVD.

Bearings

- Sealed-for-life ball bearings;

- Inboard (standard) or outboard (on heavy-duty models) to isolate from product zone and support easier servicing.

Shaft Seal

- Gland packing with PTFE as standard.

- Optional lip seals with air purge or SAS-II sanitary shaft seals for hygiene-critical environments.

Drive

- SEW direct drive as standard for compact, low-maintenance setup.

- Chain drives available upon request. Drive options sized to torque requirements

Our Range of Solutions

AL/AXL DMN-WESTINGHOUSE

AL/AXL Dairy DMN-WESTINGHOUSE

Read More

AL/AXL Dairy MZC With Slide Rails DMN-WESTINGHOUSE

Read More

AML DMN-WESTINGHOUSE

USAL DMN-WESTINGHOUSE

Blowing Seal – BL/BXL/BXXL DMN-WESTINGHOUSE

Blowing Seal BL/BXL/BXXL Dairy MZC With Slide Rails DMN-WESTINGHOUSE

MLD DMN-WESTINGHOUSE

MALD DMN-WESTINGHOUSE

SAL DMN-WESTINGHOUSE

GL DMN-WESTINGHOUSE

DL DMN-WESTINGHOUSE

Why Choose LGPM for Rotary Valves?

With over 50 years of experience in bulk material handling, LGPM has a strong foundation in designing and delivering pneumatic conveying systems and components. With heritage dating back to1968 between Lynchborough Corporation and GPM Australia, we continue to support industries with practical, engineered systems.

Related Applications

Frequently Asked Questions

What sizes do DMN-WESTINGHOUSE rotary valves come in?

Rotary valves are available in a variety of sizes, typically ranging from 100mm to 500mm, allowing for precise control across different material flow rates and system requirements.

How easy is it to maintain or replace rotors and seals?

DMN-WESTINGHOUSE rotary valves feature modular designs and adjustable-blade rotors, allowing for quick replacement of rotors, seals, and bearings. The SAS-II sanitary air-purge shaft seal includes a stainless-steel cover to prevent overtightening and supports easy maintenance in hygiene-sensitive applications.

What temperature range can DMN-WESTINGHOUSE valves handle?

Standard AL/AXL and BL/BXL rotary valves operate up to +150 °C. Special configurations are available for extreme conditions, extending the range from −200 °C to +600 °C, making them suitable for high-temperature or cryogenic processes.

Are accessories available for DMN-WESTINGHOUSE rotary valves?

Yes. Accessories include inlet restrictors, vent boxes, pressure regulators for purged seals, and rotor-interference detection systems. These add-ons improve safety, system control, and overall performance.

Do DMN-WESTINGHOUSE rotary valves meet food-grade and safety standards?

Absolutely. Many models comply with USDA, EHEDG, ATEX 2014/34/EU, NFPA 69, and EC 1935/2004, making them suitable for hygienic applications and hazardous environments.

How do I ensure air leakage is minimised in my system?

Choose a valve with tight tolerances, proper rotor-to-housing clearances, and consider air-purged shaft seals. DMN-WESTINGHOUSE models like the SAS-II are specifically designed to control air leakage in pressure, and vacuum-based systems.

Request a Quote

Don’t hesitate to get in touch with us – we’re here to answer your questions and provide the support you need.