https://lgpm.com.au/wp-content/uploads/2021/11/Copy-of-Blog-featured-image.png

363

495

Marketing Team - LGPM Process Innovation

https://lgpm.com.au/wp-content/uploads/2023/03/logo.svg

Marketing Team - LGPM Process Innovation2021-11-19 16:54:422021-11-19 16:54:44Happy National AgDay | Celebrate Aussie farming!

https://lgpm.com.au/wp-content/uploads/2021/11/Copy-of-Blog-featured-image.png

363

495

Marketing Team - LGPM Process Innovation

https://lgpm.com.au/wp-content/uploads/2023/03/logo.svg

Marketing Team - LGPM Process Innovation2021-11-19 16:54:422021-11-19 16:54:44Happy National AgDay | Celebrate Aussie farming!Planning a Project

Contact usStock feed

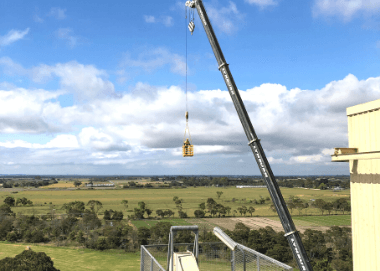

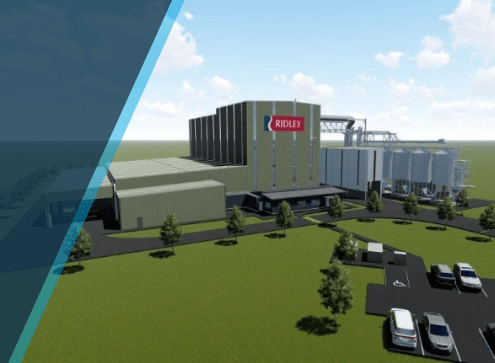

LGPM has extensive expertise in the automation of stock feed processing. We can provide a reliable and optimised solution for your entire production process.

All LGPM process lines and manufacturing plants are tailor-made to satisfy the unique needs of the customer. We will provide a detailed consultation with the client on existing and future needs and local conditions.

Our Benefits for the Industry

Safer and reliable processing

Turn-key solutions to satisfy the

unique needs of your plant

Excellent after-sales support

When designing a customer specific plant approach, we often take into account:

- Reliable processing

- Cost efficiency

- Uniform feed pellet quality

- High-performance animal feed

- Shifting availability of feed ingredients

- Increasing number of environmental standards and hygiene regulations

- The requirement for traceability in the interests of food safety

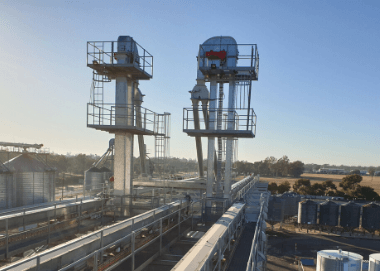

See some of our common stock feed industry applications as shown below:

- Raw ingredient receival and storage for products like Grains, Meals and minor ingredients. Silos can be fabricated in stainless steel, mild steel bolted or fully welded.

- Pneumatic conveying systems in positive pressure and vacuum.

- Mechanical conveying including screw conveyors, drag conveyors, buck elevators and belt conveyors.

- Course and Fine grinding systems via Hammermills or Roller mills

- Mixing systems including single and twin shaft paddle mixers and ribbon mixers.

- Batch weighing systems

- Micro ingredient dosing systems

- Pelletising systems utilising the latest technology from Andritz and Buhler.

- Extrusion systems including supply and installation from world leading manufacturers like Wenger, Andritz and Buhler.

- Geelen Drying and Cooling systems.

- Dinnissen vacuum liquid coating systems.

- Bulk Bag handling systems including discharging and trade approved filling machines

- IBC Handling systems

- Packing machines

- Sifters available in vibrating screen and centrifugal type

LGPM has extensive experience in designing and installing equipment to meet all Dust Hazardous Area codes.

Your satisfaction is our top priority. That is why LGPM has a team of expert after sales team to attend to the needs and wishes of our customers and ensure that the system and machines are supported throughout their service life.

Related Projects

What’s Happening At LGPM Process Innovation?

We are committed to being more than a bulk materials handling and processing company; we aim to be thought leaders in our industry by providing our clients with continuous insight, sharing the latest trends and communicating updates on technology, safety standards and regulations.