- Home

- /

- Products

- /

- Uncategorized

- /

- Bulk Bag Discharging

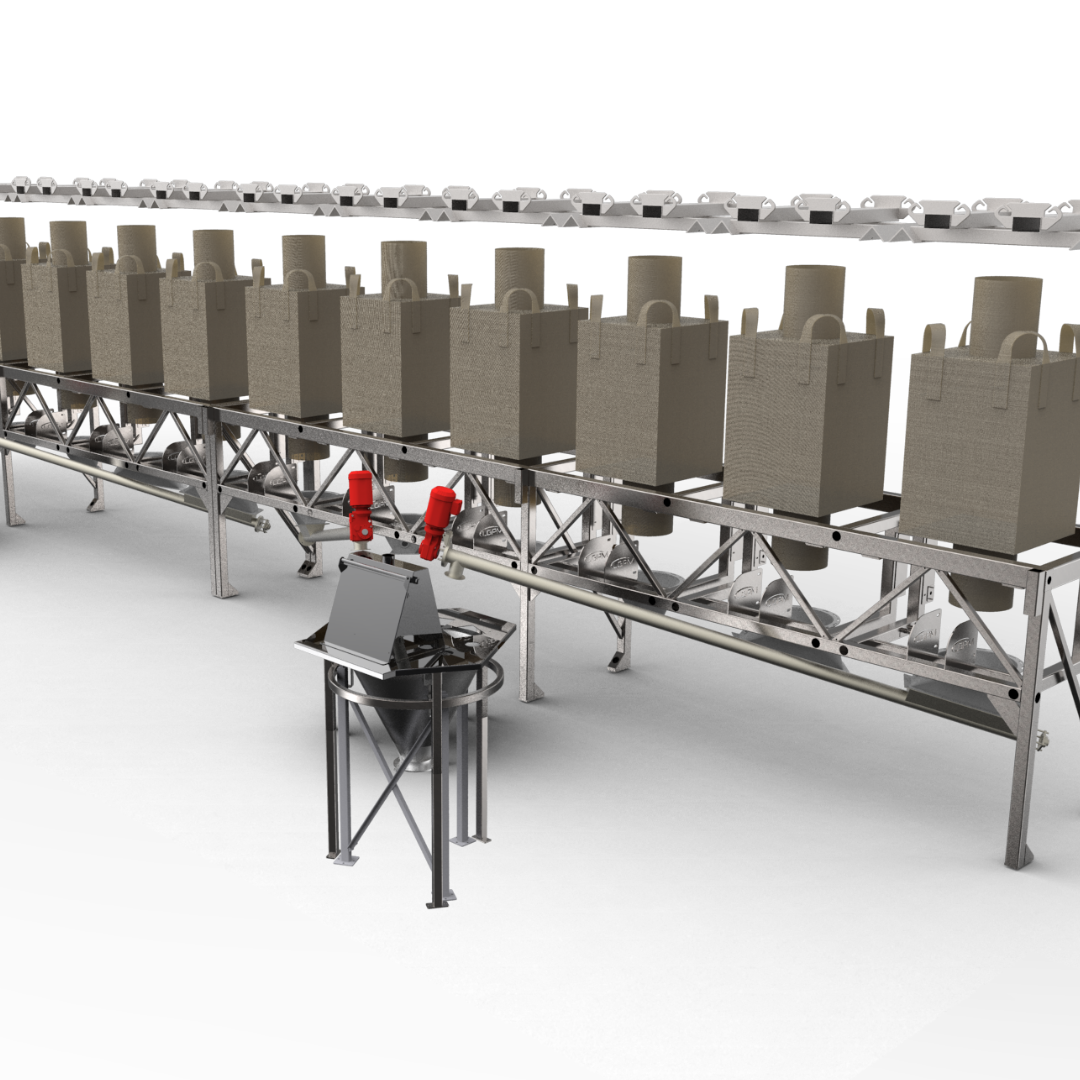

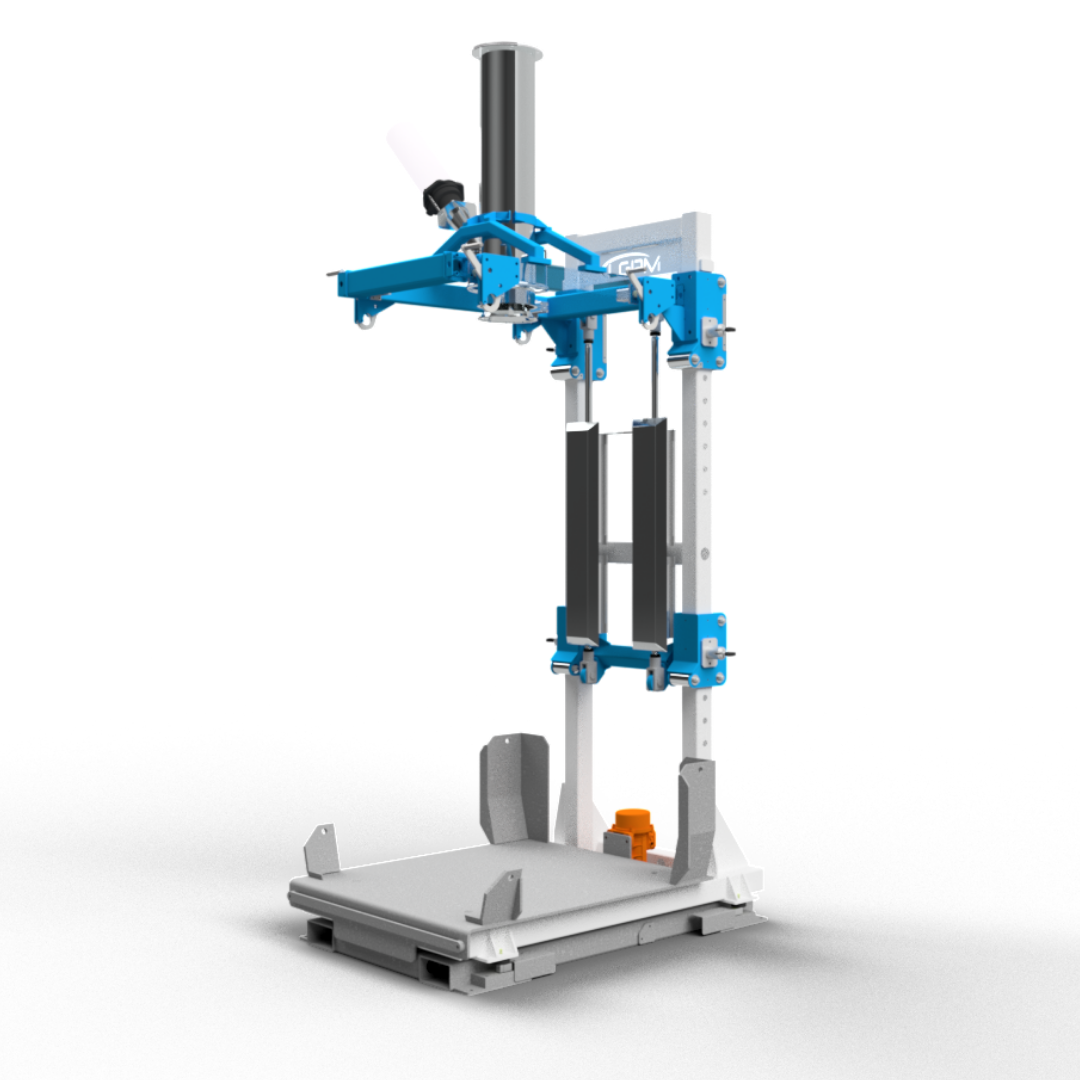

Bulk Bag Discharging

At LGPM, we offer Bulk Bag Discharging stations engineered for optimal usability and efficiency. Our designs will allow you to easily load your bulk bags via forklift or hoist. The product is then discharged into a vibrating hopper to aid flow.

Our Benefits for your Application

Vibrating discharge hopper to promote flow of difficult products.

Three bag placement options: Forklift, Monorail Hoist snd Slewing jib.

Fully supported bag to ensure safe untying of bags in accordance with Australian Standards and OH&S requirements.

LGPM has a wealth of experience in bulk bag discharging. These can be integrated into a total system to reduce manual handling of raw ingredients and increase efficiency. All units available in mild steel galvanized or powder-coated, stainless steel contact parts or full stainless steel.

- Fully supported bag to ensure safe untying of bags in accordance with Australian Standards and OH&S requirements.

- Clean design frame

- Membrane seal to the bottom of the bag to reduce dust

- Vibrating discharge hopper for flow promotion on difficult products

- Hinged access door for bag untie with window

Options:

- Integrated dust collection

- Liner tensioner

- Integrated sack tip module

- FlowStop module for bag spout clamping