- Home

- /

- Products

- /

- Uncategorized

- /

- Bulk Bag Filling

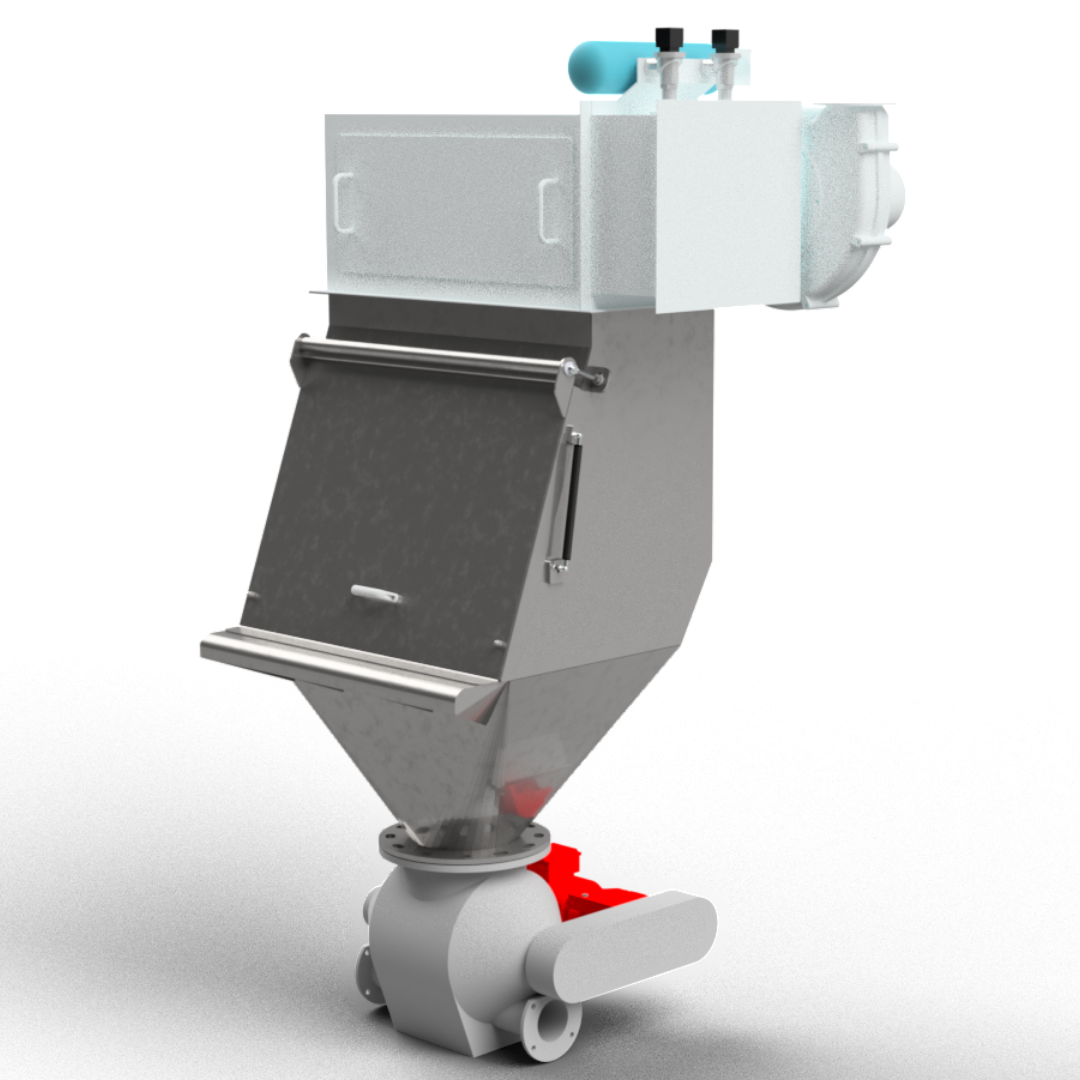

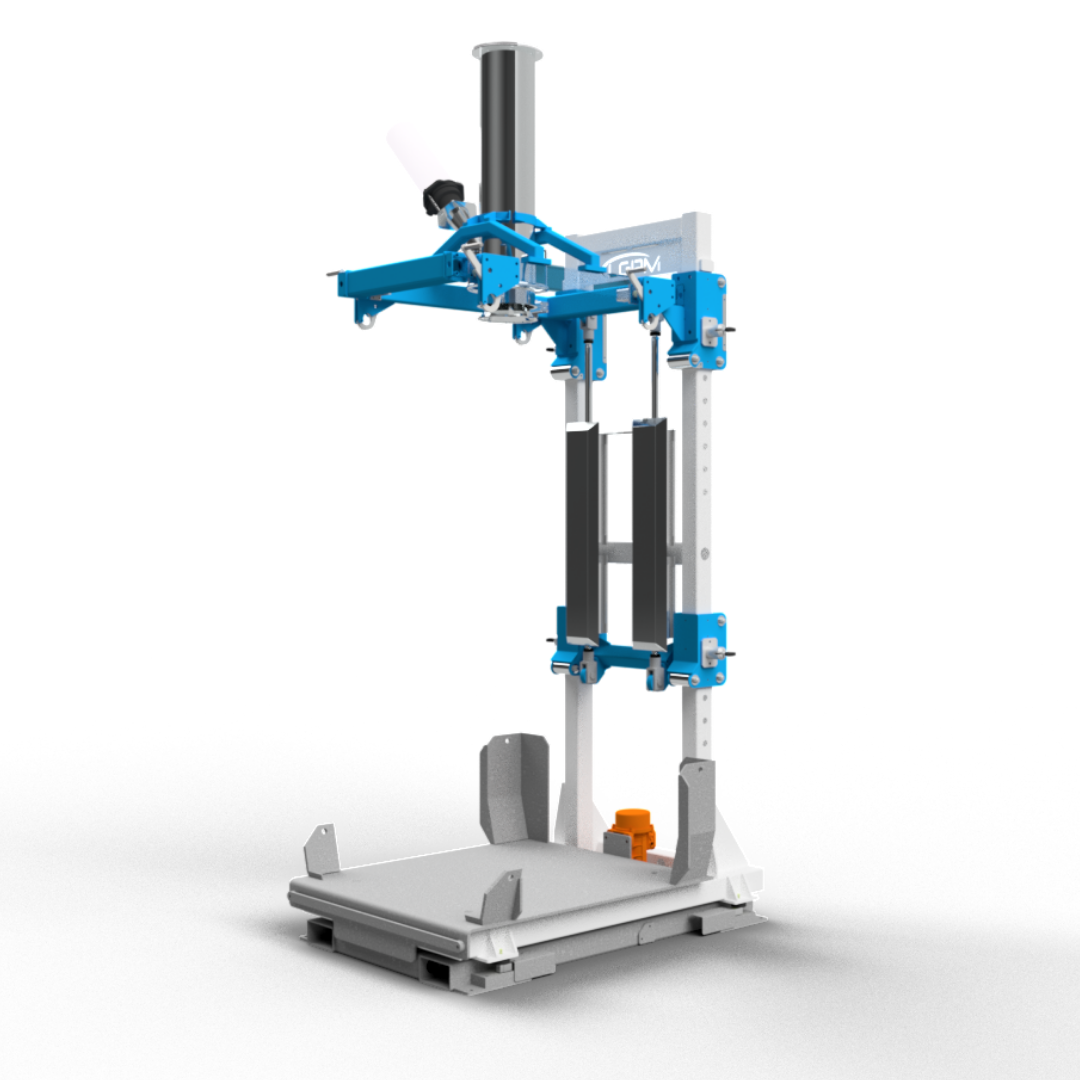

Bulk Bag Filling

At LGPM, we offer Bulk Bag Filling stations engineered for optimal usability and efficiency. Our stations are designed to fill up to 10 x 1-tonne bulk bags per hour. The process is driven via a smart touchscreen control panel with automatic control.

Our Benefits for your Application

Touch screen control panel with automatic filling system.

Capable of filling up to 10 TPH (10 off 1 tonne bags)

Automatic bag stretch cycle during filling to ensure a firmly packed bag for stacking and shipping & Automatic bag inflation before filling.

LGPM has a wealth of experience in bulk bag Filling. These can be integrated into a total system to reduce manual handling of raw ingredients and increase efficiency.

The original Floveyor conveyor is manufactured to the highest standards of safety, compliance, and ease of use with the ability to gently and rapidly convey dry powders and granules.

- Fork Lift Pockets in the base frame for mobility

- Pallet Vibrating Tray to compact material during the filling cycle

- Pallet locators to suit CHEP type pallet

- Bag Support Frame allows user to suspend the bag at 4 points with self-locking and auto release hooks for quick bag changeover

- 2 bag height options are selectable via the touch screen. Bag height setpoint adjustable via spring-loaded locking pins.

- Automatic bag stretch cycle during filling to ensure a firmly packed bag for stacking and shipping.

- Automatic bag inflation before filling.

- Four (4) load cells 1,500KG capacity with Rinstrum Weigh Controller

- Interface filling spout & bag neck

- The automatic inflatable bag neck seal

- Integrated Control System & wiring including touch screen control panel with the automatic filling system.