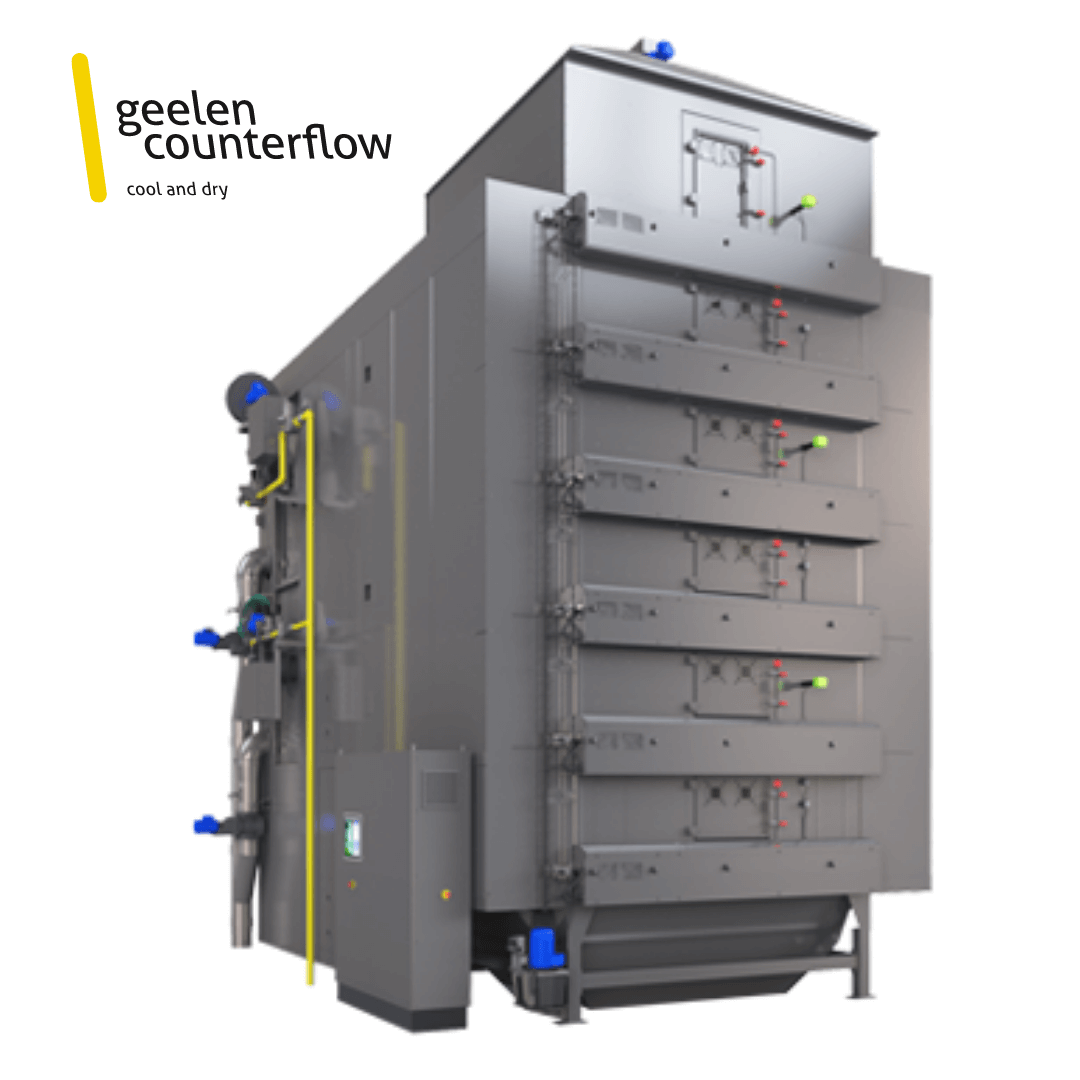

Batch Dryer Geelen

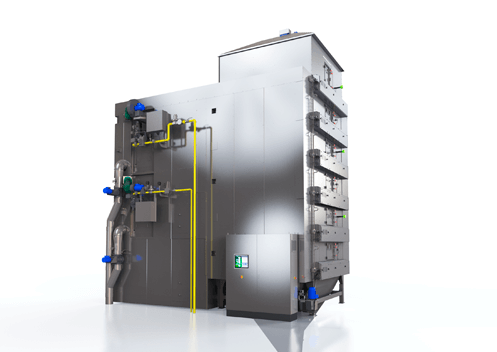

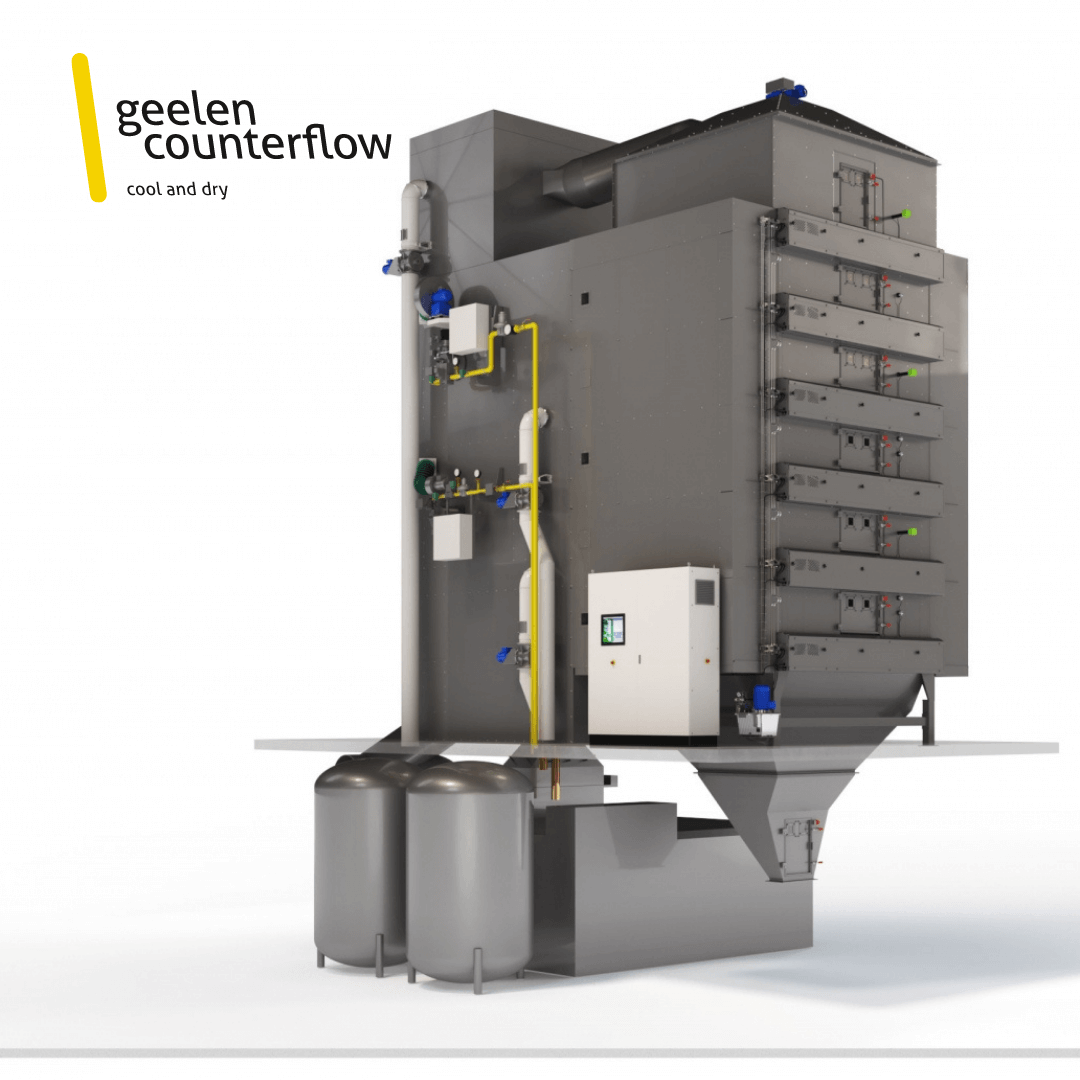

At LGPM, we offer Geelen Counterflow batch dryers. The batch dryer operates by forcing hot air through 5 to 10 product beds. The new product is continually supplied to the top bed deck, converting the continuous flow into a series of batches.

Our Benefits for your Application

For high capacity and fast change-overs

Excellent flexibility

Minimal maintenance

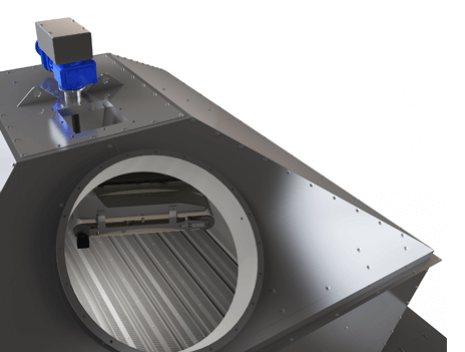

Timer-driven and hydraulic cylinders control the discharge from each bed deck. Discharging begins on the lowest deck and passes through the upper decks sequentially to ensure that there can be no cross-contamination of the substance. Each product batch is processed individually in isolated drying zones. Variations in the volume and temperature of the drying air will regulate the quantity of evaporation on each deck.

To enhance final product moisture monitoring, a moisture sensor at the dryer outlet may serve as an input for the heater temperature setpoint. With high relative humidity, a regulated amount of drying air is depleted while the remaining air is recycled back to the heaters. This maximises the Geelen Counterflow dryer’s energy efficiency.